Vegetable Plastic Crates: A Practical Guide For Agriculture And Cold Chain Storage

introduction

From harvesting to warehouse storage and long-distance delivery, vegetables face a range of challenges: crushing, moisture buildup, and inefficient stacking. Choosing a well-structured plastic vegetable crate can help preserve quality, improve handling, and reduce logistics costs.

This guide walks you through how vegetable crates are used in real operations and how to select the best model for your needs. It's especially valuable for farm owners, produce exporters, and cold chain logistics providers.

What Are Vegetable Crates and Why Do They Matter?

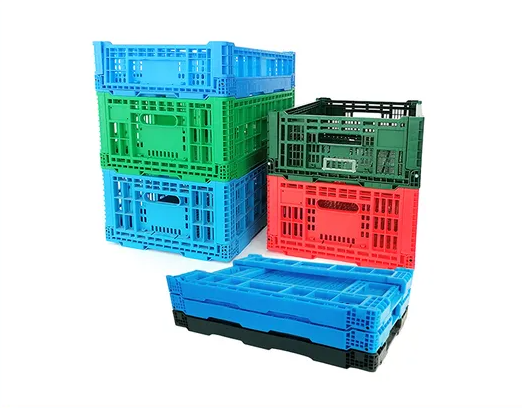

Vegetable plastic crates are containers made from HDPE or PP, specifically engineered to protect fresh produce during storage and transportation. These crates offer lightweight, high durability, and compliance with food-grade standards.

Popular options include solid-wall crates for added protection, vented fruit crates for airflow and freshness, and foldable crates that save return-trip space. Far more than just "boxes," these are purpose-built tools for supply chain efficiency and hygiene.

Where Do Plastic Crates Fit Into the Produce Supply Chain?

Plastic crates are used at every stage-from the field to the shelf. In harvesting, breathable crates reduce damage to leafy greens and soft fruits.

During sorting and packing, stackable crates help organize produce and improve workflow.

Cold storage facilities benefit from uniform-sized crates that stack safely and ensure airflow.

For cross-border transport, foldable crates are especially useful, as they reduce return freight volume and storage space.

What Are the Key Benefits of Plastic Vegetable Crates?

Unlike cardboard or wooden boxes, plastic crates are reusable and remain stable in wet or refrigerated environments.

Their rigidity prevents deformation, making them ideal for high-turnover operations.

With easy-to-clean, moisture-resistant surfaces, plastic crates meet food safety standards and minimize the risk of mold and bacterial growth.

Foldable crate designs lower storage and return transport costs. In the long run, these crates save money while improving logistics performance.

Beyond Vegetables-Where Else Are These Crates Used?

Thanks to their strength, hygiene, and space-saving design, vegetable crates are widely adopted in seafood processing, baked goods distribution, beverage factories, and more.

For example, vented crates are used to drain excess water in seafood; solid-wall foldable crates are used in bakeries; reinforced PP crates are used to transport bottled drinks.

Plastic foldable crates are not only ideal for transporting fruits and vegetables-they're also widely used as milk crates in the dairy industry, especially for bottled or bagged milk during cold chain distribution. If you're looking for a durable, easy-to-clean container suitable for refrigerated logistics.

Check out our detailed guide on milk crate applications.

https://www.cnplasticpallet.com/news/what-type-of-plastic-are-milk-crates-made-from-80909563.html

It's not just about what's inside-their performance shines in demanding, fast-paced environments.

How to Choose the Right Crate for Your Produce?

Leafy greens and herbs do best in vented turnover crates that keep air flowing during stacking.

Root vegetables like potatoes and carrots need solid crates that resist deformation under weight. Delicate items such as tomatoes and berries benefit from smaller, reinforced crates that reduce damage during transport.

If reverse logistics is part of your operation, collapsible crates are highly recommended to save on shipping and storage. Handling multiple types of produce? Use modular crates sized to match standard pallets to simplify stacking and truck loading.

How Are These Crates Manufactured?

Most plastic crates are made using injection molding. Heated PP resin is injected into precision molds to ensure consistent size, structure, and strength. High-quality crates have uniform wall thickness, stable corners, and reinforced bases to support vertical stacking.

Enlightening Pallet also offers crate customization, including structural tweaks, new mold development, and logo printing-ideal for scaling operations or building brand identity.

Choose the Right Crate, Partner with the Right Manufacturer

Switching from disposable packaging to plastic crates is a smart move, but it only pays off if you choose the right supplier.

Enlightening Pallet specializes in developing plastic vegetable crates tailored for durability, airflow, and stackability. Whether you're dealing with reverse logistics costs, mixed-size produce, or limited warehouse space, we can help you find the best solution for your application and budget.

Contact us to tell your crop, your process, and your goals-we'll design a crate system that works for you.